|

linyi ruihe doors and windows co.ltd

|

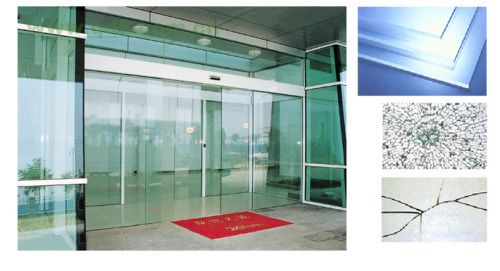

tempered glass for door

| Payment Terms: | T/T,L/C,WU |

| Place of Origin: | Shandong, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

As an experienced glass deep processing company ,we are engaged in the operation of LED glass,tempered glass /toughened glass,insulating glass,etc

Tempered Glass

1. thickness: 3mm-19mm

2. color: clear, white, grey, blue, etc.

3. standard: GB/15763.2

4. quality: top-grade

1. thickness: 3mm-19mm

2. color: clear, white, grey, blue, etc.

3. standard: GB/15763.2

4. quality: top-grade

Tempered Glass

Tempered glass is made from float glass. After heated to its softening point, float glass is cooled rapidly and homogeneously so that the glass surface gets compressive stress. In the cooling process, the external part of tempered glass is rapidly cooled and solidified, while the internal part is cooled slowly. So, when the internal part keeps on cooling and shrinking, compressive stress forms in the glass surface and tensile stress inside, so as to improve the strength and the thermal stability of glass.

Features:

1. High strength: Compared with ordinary glass of the same thickness, tempered glass has 3-5 times higher flexural strength and impact strength. For the strongest tensile stress is in the center of glass panel rather than in the glass surface, tempered glass is hard to break under the some load.

2. Safety: The compressive stress improves the strength of tempered glass, so that the glass is not easily broken when attacked. Even if it is broken under load, the cullet is tiny and obtuse, and causes no harm to human bodies.

3. Heat shock resistance: Compared with ordinary glass of the same thickness, tempered glass has 3 times higher heat shock resistance. It can bear the temperature changing from 220°C-250°C, while ordinary glass bears only 70°C-100°C. As it can resist some sudden change of temperature, tempered glass plays an important role in fire resistance for a short time when a fire breaks out.

4. In line with GB/15763.2 for tempering.

Related Search

Tempered Glass Door

Glass Door

Tempered Shower Door

Tempered Glass

Glass Sliding Door

Glass Steel Door

More>>